Valve Seal

Valve Seal Definition And Characteristics

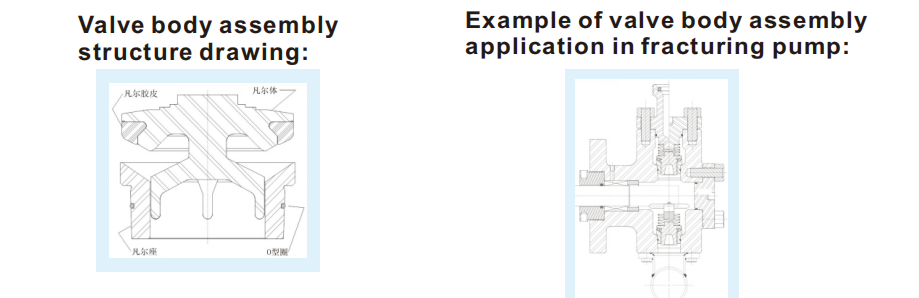

As a necessary vulnerable part of fracturing truck, well cement truck, plunger pump, mud pump and other petroleum equipment. Its product features mainly have the following points:

ü High tensile strength and tear strength

ü Good resistance to compression and permanent deformation

ü Good static and dynamic sealing performance

ü Good resilience, low friction coefficient, wide range of temperature adaptation, not only good water and oil resistance, but also acid and alkali resistance;

Valve Seal Service Condition:

At present, Types of fracturing fluids used for fracturing operations include water-based fracturing fluid, oil-based fracturing fluid, alcohol-based fracturing fluid, emulsified fracturing fluid, foam fracturing fluid, energy-enhancing fracturing fluid, etc., regardless of the type of fracturing fluid, they contain more than ten additives, complex ingredients, and require the fracturing fluid to be good at carrying sand. The performance and service life of Valve Seal is the key to ensure the normal operation of fracturing equipment, and in the whole fracturing process, the maximum construction pressure can reach more than 100 Mpa, and each period of construction time can reach 2-3 hours, cumulative construction work up to 25-30 hours, operating pressure, long working time, bad working conditions, which put forward very harsh requirements for the use of Valve Seal.

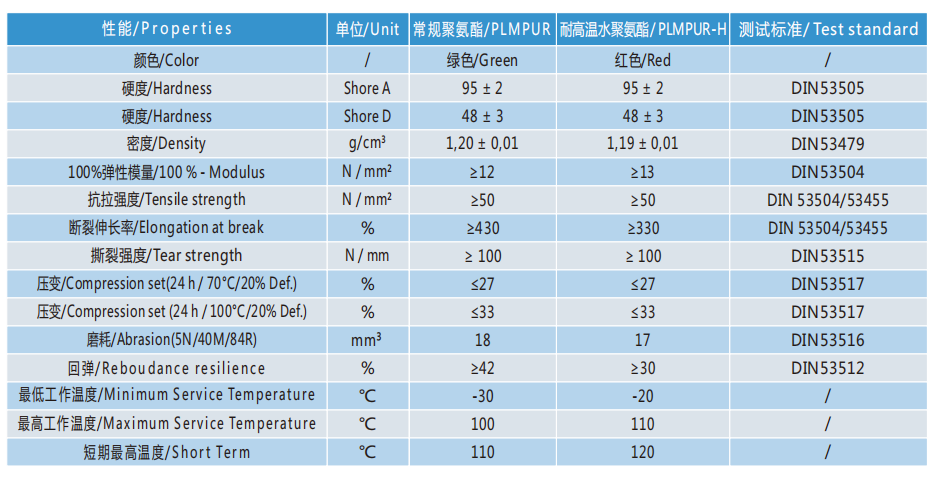

Valve Seal Physical Parameter:

Suzhou PULIM Sealing Technology Co,Ltd. developed high quality polyurethane material, with excellent wear resistance, extrusion resistance fatique resistance and medium resistance, for petroleum industry fluids (including acidic media or liquid nitrogen) also has excellent compatibility.

Remarks: PLMPUR suitable for acid content less than 10% condition. PLMPUR-H suitable for acid content more than 10% condition.

Regular Valve Seal:

At present, there are two processing methods for Valve Seal: mold free turning and injection molding, Mold free turning has the characteristics of fast response and no batch requirement, Injection molding is characterized by low unit price, stable size and high production efficiency, which can effectively reduce fracturing costs for the owner. Our company can provide Valve Seal of mold free turning and Valve Seal of injection molding, is a supplier of high quality parts to the petroleum industry.

PLMPUR-Modified Valve Seal:

In areas where fracturing is more difficult, Valve Seal is need to bear increased pressure, higher temperatures, and constant work in concentrated acid environments. PULIM has developed modified material Valve Seal for such harsh conditions, which can effectively improve the continuity of on-site production.

Контактное лицо:Pulim

Контактное лицо:Pulim телефон:+86-18913273753

телефон:+86-18913273753 факс:+86 (512) 66333988

факс:+86 (512) 66333988 Эл. почта:sales@pulim.cn

Эл. почта:sales@pulim.cn Добавить:улица Хуаян, 155, район Сянчэн, Сучжоу, Китай

Добавить:улица Хуаян, 155, район Сянчэн, Сучжоу, Китай

ДОМА

ДОМА Продукты

Продукты КОНТАКТ

КОНТАКТ