Thermoplastic/PTFE (PLMFLON series)

Suzhou Pulim Sealing Technology Co. Ltd. offers a wide range of standard compounds, the majority of which have been developed, and are produced, in our own production plant.

Suzhou Pulim Sealing Technology Co. Ltd. is specialised in advanced engineered plastics products. The offer goes from turned, milled and moulded parts to advanced and standard engineered plastic parts, using in-house developed and produced range of materials.

The Thermoplastic Elastomers demonstrate the characteristic properties of elastomers over a wide temperature range, but with the processing behaviour of thermoplastics. They can be melted at high temperature and can be processed with traditional thermoplastic processing techniques. Thermoplastic elastomers are soluble and they generally swell less in comparison to their chemically crosslinked equivalents. Thermoplastics can be melted. They are polymer materials, which are essentially harder and rigid at their application temperature compared to elastomers. Depending on the chemical structure, the properties vary from hard, to stiff, to ductile and flexible. Due to the morphological structure, extensive stretching is non-reversible and moulded parts remain in the deformed state. Thermoplastics are therefore called Plastomers. Engineering Thermoplastics are applied in the sealing technology for back-up rings and guide rings, bearing bushes, etc.

PULIM PTFE are mainly used for back-up rings, guide rings, bushings, bearings and engineered parts. Many have outstanding resistance to high temperatures and chemicals, offer excellent sliding properties and can absorb high radial forces. Therefore they are often also referred to as engineering plastics.

Standard:

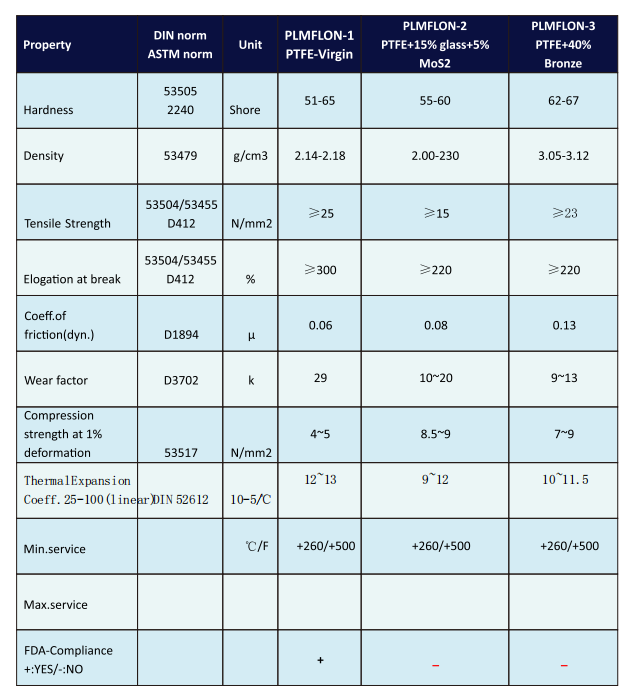

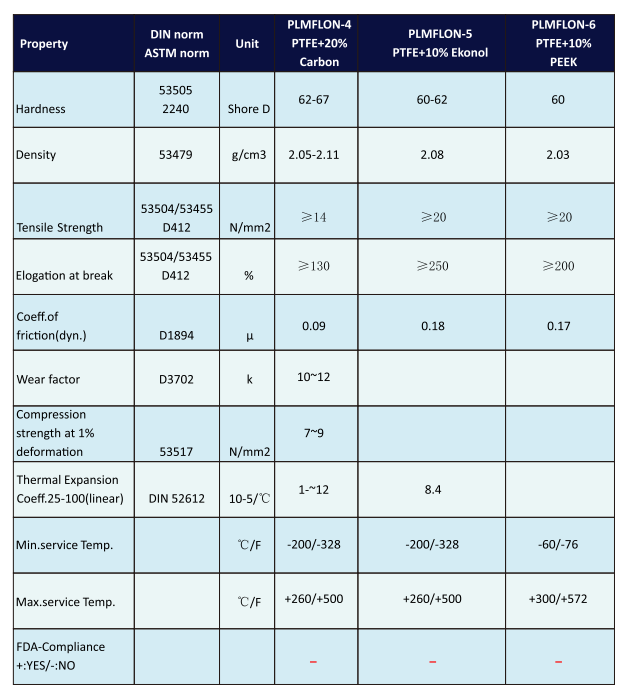

PLMFLON-1 PTFE-Virgin | PLMFLON-2 PTFE + 15% glass + 5% MoS2 | PLMFLON-3 PTFE + 40% Bronze | PLMFLON-4 PTFE + 20% Carbon | PLMFLON-5 PTFE + 10% Ekonol | PLMFLON-6 PTFE + 10% PEEK

INNOVATION. PLM Modified. PTFE

PLM-M-FLON-1 modified. PTFE -Virgin | PLM-M-FLON-2 modified. PTFE + 15% Glass fiber

1) PLMFLON-1 (white) PTFE-Virgin

PLMFLON-1 is based on polytetrafluorethylene. Due to its composition, it has the widest application range of all sealing materials. It has an outstanding chemical resistance and is only susceptible to molten alkali metals and elementary fluorine at high temperatures. PTFE has a tendency to creep and can absorb relatively low pressure loads. PLMFLON-1. is suitable for applications in contact with foodstuffs and is also used in many applications in the healthcare and pharmaceutical industries.

2) PLMFLON-2 (grey) PTFE + 15% glass + 5% MoS2

PLMFLON-2 is a PTFE filled with 15% glass and 5% MoS2 in order to improve its compression strength, extrusion resistance and sliding properties in comparison with PTFE-virgin. The chemical resistance remains similar to PLMFLON-1. Glass-filled PTFE compounds have an abrasive effect on their mating surfaces, especially in rotary applications.

3) PLMFLON-3 (brown) PTFE + 40% Bronze

PLMFLON-3 is a PTFE filled with 40% bronze in order to improve its compression strength and has an improved thermal conductivity as well as excellent wear resistance compared with PTFE-virgin. Bronze-filled PTFE has higher friction and poorer chemical resistance than other filled PTFE compounds.

4) PLMFLON-4 (black) PTFE + 20% Carbon

PLMFLON-4 is a PTFE filled with 20% carbon, which gives it excellent compression strength, good thermal conductivity and low permeability. Carbon-filled PTFE is less abrasive than glass-filled PTFE and has excellent wear and friction properties especially combined with graphite.

5) PLMFLON-5 (cream) PTFE + 10% Ekonol

PLMFLON-5 is a PTFE filled with 10% Ekonol. lt has good wear and extrusion resistance, especially in dry running conditions. It has similar chemical resistance, and can be used in same temp. range, as pure PTFE, especially in rotary applications at high speeds. It should not be used in hot water.

6) PLMFLON-6 (tan) PTFE + 10% PEEK

PLMFLON-6 is a PTFE filled with 10% PEEK. It has good chemical resistance, high creep strength and high wear resistance. PLMLFON-6 is mainly used for applications requiring very high resistance.

Контактное лицо:Pulim

Контактное лицо:Pulim телефон:+86-18913273753

телефон:+86-18913273753 факс:+86 (512) 66333988

факс:+86 (512) 66333988 Эл. почта:sales@pulim.cn

Эл. почта:sales@pulim.cn Добавить:улица Хуаян, 155, район Сянчэн, Сучжоу, Китай

Добавить:улица Хуаян, 155, район Сянчэн, Сучжоу, Китай

ДОМА

ДОМА Продукты

Продукты КОНТАКТ

КОНТАКТ