Polyurethanes (PLMPUR series)

Polyurethanes play an important role in today's sealing technology. They have gained an important market share in the global seal market and are mainly used as piston and rod seals(U-cups), wipers and primary sealing element in composite seals.

PULIM Sealing Technology is able to offer our customers a wide range of polyurethane compounds. Our manufacturing technology guarantees the development of excellent physical properties during polymerization, which results in outstanding material quality.

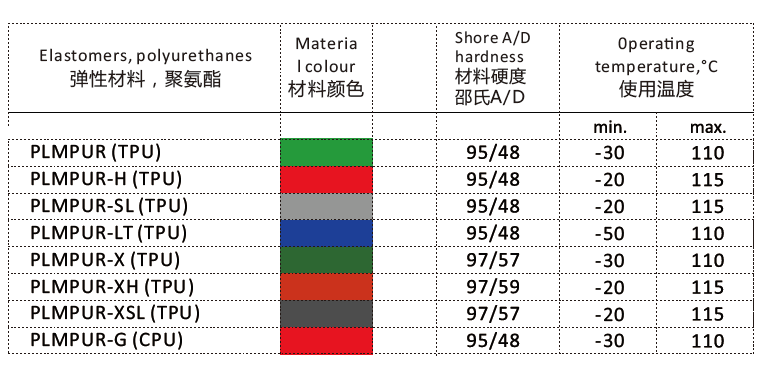

PLMPUR (TPU) | PLMPUR-H (TPU) | PLMPUR-SL (TPU) | PLMPUR-LT (TPU) | PLMPUR-X (TPU) | PLMPUR-XH (TPU) | PLMPUR-XSL (TPU) | PLMPUR-G (CPU)

Materials overview:

1) PLMPUR (TPU) green

PLMPUR is a thermoplastic polyurethane elastomer, with an excellent abrasion resistance, low compression set, outstanding tensile properties and tear strength. PLMPUR is mostly used for U-cup seals, lip seals, wipers and chevron packings, but it may also be used for dampers and other machined parts. It has a very good resistance against hydraulic fluids based on mineral oils, however in applications with water-based fluids (e.g. HFA, HFB) and native liquids (vegetable oils) a temperature of 60°C should not be exceeded.

PLMPUR is produced by injection moulding and shows a very good machinability.

2) PLMPUR-H (TPU) red

PLMPUR-H is a hydrolysis-resistant thermoplastic polyurethane elastomer. It combines the engineering properties of PLMPUR (outstanding physical properties) with a high chemical resistance against a broad range of fluids. It is resistant against hydrolysis (degradation in water) which is otherwise rare when it comes to polyurethane's. E.g. it is stable in water up to +90°C and has an outstanding stability in mineral oil as well. Because of its resistance to hydrolysis PLMPUR-H can be used for water hydraulic and for applications in mining, tunnelling and manufacturing of presses. PLMPUR-H is particularly recommended for the use in pure and seawater, for HFA and HFB fluids and biologically degradable hydraulic fluids (vegetable oils and synthetic esters) and food articles. PLMPUR-H is in conformance with various food regulations and can be used for many food-, beverage- and healthcare applications.

PLMPUR-H is produced by injection moulding and shows also a very good machinability.

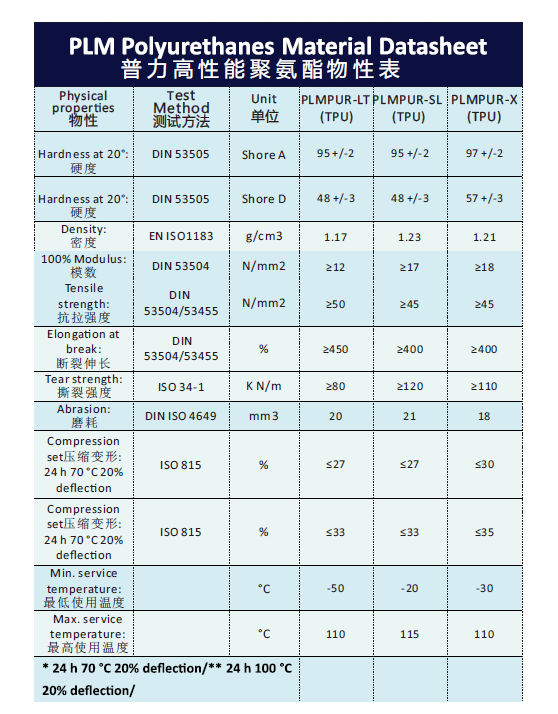

3) PLMPUR-SL (TPU) grey

PLMPUR-SL (TPU) has been optimised in regard of the tribological characteristics (friction and wear), achieved by an addition of a synergetic combination of solid lubricants. Compared to PLMPUR-H, PLMPUR-SL has superior sliding properties. This special material is therefore best suited for most severe applications in the water hydraulics as well as in the non-lubricated pneumatics.

4) PLMPUR-LT (TPU) blue

PLMPUR-LT is a thermoplastic polyurethane elastomer, that has been developed for low temperature applications. The physical and chemical properties of PLMPUR-LT are similar to those of PLMPUR, but the minimum service temperature is extended to -50°C. For that reason PLMPUR-LT should be used under severe climatic conditions and for applications in freezing plants.

5) PLMPUR-X (TPU) dark green

PLMPUR-X is a thermoplastic polyurethane elastomere and has a significantly higher hardness compared to the standard PLMPUR grade. The composition of the material provides outstanding friction and wear properties as well as high pressure resistance. Therefore the material is well suited for the use as a composite seal, for wipers working in heavy-duty applications as well as for engineered plastic parts that need high elasticity and superior resilience behaviour. Due to the exceptional extrusion resistance seals made of this material are working at higher pressure levels and larger clearances than those made of standard polyurethanes and PTFE compounds.

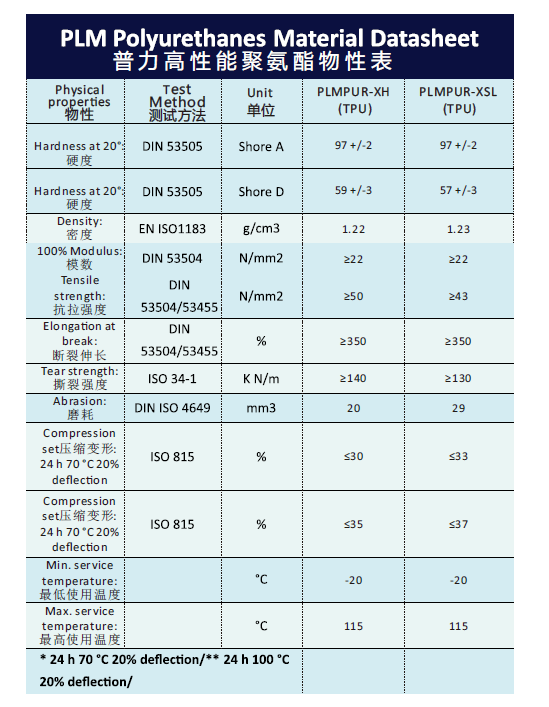

6) PLMPUR-XH (TPU) dark red

Compared to the standard grade PLMPUR-H, PLMPUR-XH has a significantly higher hardness. The composition of the material based on special raw material provides outstanding friction and wear characteristics as well as pressure resistance.

7) PLMPUR-XSL (TPU) dark grey

Compared to the PLMPUR-SL standard material, PLMPUR-XSL has a higher hardness and therefore further improved sliding properties. PLMPUR-XSL has a better extrusion resistance than the standard material and therefore sealing elements of this material can be used at higher pressures.

8) PLMPUR-G (CPU) red

PLMPUR-G is a cast hydrolysis-resistant polyurethane elastomer with similar properties to PLMPUR-H especially regarding its chemical stability. Therefore PLMPUR-G can be used in the same hydraulic fluids as PLMPUR-H.

Контактное лицо:Pulim

Контактное лицо:Pulim телефон:+86-18913273753

телефон:+86-18913273753 факс:+86 (512) 66333988

факс:+86 (512) 66333988 Эл. почта:sales@pulim.cn

Эл. почта:sales@pulim.cn Добавить:улица Хуаян, 155, район Сянчэн, Сучжоу, Китай

Добавить:улица Хуаян, 155, район Сянчэн, Сучжоу, Китай

ДОМА

ДОМА Продукты

Продукты КОНТАКТ

КОНТАКТ