Cause Of The Sealing Failure Of The Rubber Seal Member

2024-05-05

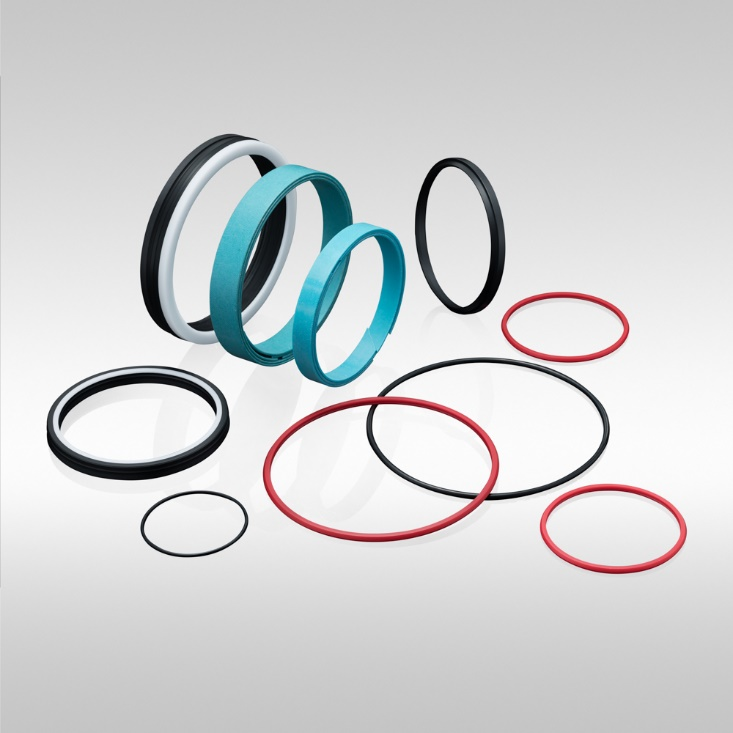

In the hydraulic transmission system, various parts are in a closed state. If there is a problem, it is difficult to troubleshoot and the process is cumbersome. Most of this kind of failure is because one of the parts is damaged, causing it to fail and stop working... Rubber seals are the focus of protecting engineering parts and hydraulic systems, so their reliability is the focus of engineering personnel. Rubber is extremely resistant to compression and degeneration, and can prevent leakage of pressure media, so it has become the primary material for multi-seals. At present, rubber sealing technology is used in high-tech industries such as aerospace and petrochemical industry. Therefore, rubber has very high requirements for environmental adaptability. To effectively ensure the normal operation of mechanical equipment, the staff must attach great importance to the design and development of rubber sealing structures. The failure of most seals is due to the unreasonable rubber material or structure, which leads to seal failure, which hurts engineering operations.

damaged-rubber-O-ring-seals

1. The form of rubber seal failure

The main forms of sealing failure of rubber seals are as follows:

1) Aging. With the passage of time, the strength, compression resistance and degeneration resistance of the seals will gradually decrease, and the rubber seals will become hard or brittle.

2) Wear and tear, since the seal is mainly used in the shaft-rotating machinery, the surface is prone to scratches, and there are grooves with different depths.

3) Damage, the lip of the seal is deformed, the surface is damaged, and local fracture occurs, which eventually leads to seal failure.

worn-rubber-O-ring-seals

4) Twisted, some parts of the rubber ring seal are turned over, and grooves or protrusions appear.

5) Swelling, the lip of the seal begins to soften, become sticky, or partially peel off.

6) Ablation, carbonization of the lip of the seal, ablation of the support ring, and failure of the rubber sea.

2. Causes of seal failure of rubber seals

1) Improper selection

Rubber seals are mostly used in some high-precision industries, so quality is the first prerequisite. If some seals with inappropriate models or unqualified materials are selected, failures are likely to occur, which will affect the progress of the project.

2) Assembly quality is not high

According to the survey, more than half of the failures of rubber seals are due to problems in the installation process. Due to the lack of scientific methods during installation, components with inconsistent models are also forcibly installed, resulting in deformation of the seals and seal failure.

3) Improper storage of seals

There are strict conditions for the storage of seals. In the process of transportation, the placement of seals that do not meet the specifications is also a major cause of seal failure.

rubber-O-ring-seals-breakage

4) Unreasonable selection of oil

The contact between the oil and the rubber seal is the closest, so whether the oil is selected properly will impact the performance of the rubber seal. If the compatibility of the oil is not high, the aging, and deformation of the rubber ring will be accelerated, and the oil will be precipitated Will accelerate the wear rate of rubber seals.

5) Oil pollution

According to the standard use and maintenance method, the oil needs to be replaced regularly, so that even if the performance of the oil is maintained, the pollution of the oil can be observed in time, because if the oil pollution is serious, the rubber ring will expand and deform.

Contact:Pulim International Marketing

Contact:Pulim International Marketing Tel:+86 (512) 66333588

Tel:+86 (512) 66333588 Fax:+86 (512) 66333988

Fax:+86 (512) 66333988 E-mail:sales@pulim.cn

E-mail:sales@pulim.cn Add:No.155 Huayang Road, Xiangcheng District, Suzhou, P.R.China

Add:No.155 Huayang Road, Xiangcheng District, Suzhou, P.R.China

Home

Home Products

Products Contact

Contact