Types Of Basic Seals Used In Hydraulic Cylinders and their functions

2024-03-28

Hydraulic cylinders are machines used for reciprocation with the help of fluid power. They are known for their heavy load-carrying capacity and have tremendous applications in various industries. A simple example of a hydraulic cylinder can be taken as a shock-up of a bike. The basic elements used for sealing purposes in a hydraulic cylinder can be given below. However, the design engineer uses a combination of these basic seals for optimization.

Wiper Seals/Scraper

Wiper/Rod wiper/scraper/Dust seals are sealing elements that keep dirt or contamination out of the hydraulic cylinder. Wiper seals are fitted to the outermost part of the cylinder head. In most of the cylinders, we can see the lip of the wiper seal visible on the outer side. In the above image, you can see the wiper seal in black color.

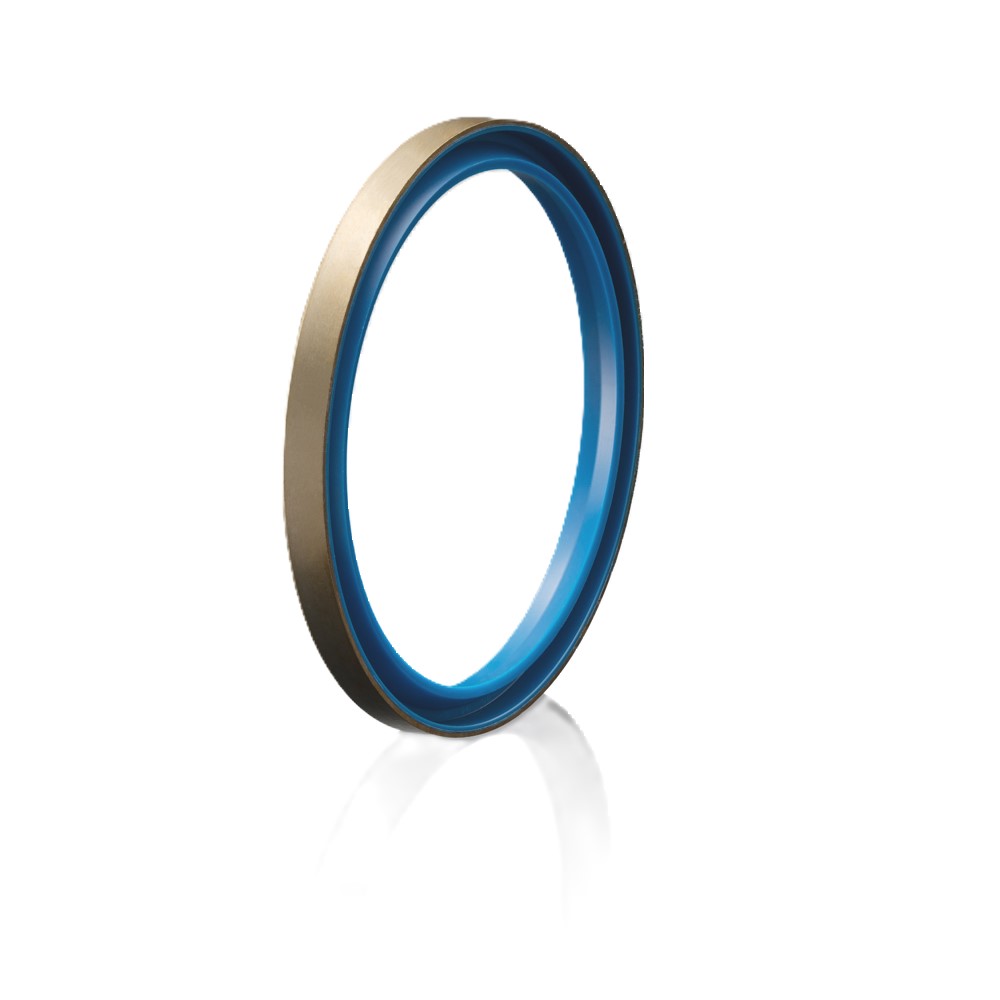

Rod Seals

Rod seals are the most important seals in the system. The rod seal takes the majority of system pressure. The most common profile of a rod seal is a U-shaped seal also called a U-seal. The lip of a rod and a wiper seal are opposite to each other as the function of a rod seal is to hold the oil from coming out of the cylinder. In the above image, you can see the rod seal in blue color.

Piston Seals

Piston seals are the seals holding oil between the piston and the bore. After rod seals, the second most important seals are piston seals. They also come in U-shapes and are hence sometimes called U-seals. U seals are single-acting seals; therefore, two are used on pistons for double-acting applications. In the above image, you can see piston seals in yellow color.

O-rings

O-rings are O-shaped rubber rings used for sealing in static applications. O-rings are also used with Backup rings to avoid extrusion in the gap. Generally, O-rings are used to seal the barrel ends and between the rod and the piston gaps.

Back-up Rings

Back-up rings are also called anti-extrusion rings. They are usually used with O-rings or U-seals to prevent extrusion.

Wear Rings/Guide Tapes

Wear rings/Guide tapes are used for the alignment of the metal parts to avoid metal-to-metal contact. They keep the system aligned so that no scratches are developed at high pressure due to metal-to-metal contact.

The above given are the basic seals to make you understand their most common functions. There is a wide range of seals that cannot be covered in this article. The selection of seals is based on application, pressure, temperature, speed of the stroke, and various other factors.

The material selected for seals, according to applications, plays a crucial role in deciding the life of these seals. For any technical discussion or doubts, please feel free to contact me.

Contact:Pulim International Marketing

Contact:Pulim International Marketing Tel:+86 (512) 66333588

Tel:+86 (512) 66333588 Fax:+86 (512) 66333988

Fax:+86 (512) 66333988 E-mail:sales@pulim.cn

E-mail:sales@pulim.cn Add:No.155 Huayang Road, Xiangcheng District, Suzhou, P.R.China

Add:No.155 Huayang Road, Xiangcheng District, Suzhou, P.R.China

Home

Home Products

Products Contact

Contact